SEE OUR GALLERY

Flat Bottom Silo

SILOPRO commercial grain bins offer many outstanding strength and durability features. Wide corrugated steel sheets manufactured from high strength steel, heavy duty galvanized steel stiffeners and strong box-rib roofs are some of the quality features available.Our complete line of commercial bins are available in diameters from 15 feet (4.57 m) to 105 feet (32 m). Extra-tall sizes are available in all diameters.

Flat bottom silos are in capacities changing between 100 tons and 15,000 tons to store all kinds of grains such as wheat, corn, rice, bean, soyabean, barley, sunflower and other free-flowing products.

Wall Sheets

SILOPRO wall sheets are in G-115 (350gr/m²) standarts and %20 heavier than the G-90 standart metal sheets. This difference not only prolongs the life of the coating,but also provides protection against external factors.

The 4"wide corrugations on Silopro sidewall sheets create less resistance and friction to allow grain to flow more easily. Silopro sheets are 44" high, so there are fewer rings, seams and bolts than bins with 32" sidewalls.

SILOPRO wall sheets have tensile strength in the range of minimum 900.000kgf/cm² (63,200 Psi) and 1.000.000kgf/cm² (70,260 Psi). These values are our obvious superiority against other silos in the market.

Stiffeners

SILOPRO wall sheets are in G-115 (350gr/m²) standarts and %20 heavier than the G-90 standart metal sheets. This difference not only prolongs the life of the coating,but also provides protection against external factors.

The 4"wide corrugations on Silopro sidewall sheets create less resistance and friction to allow grain to flow more easily. Silopro sheets are 44" high, so there are fewer rings, seams and bolts than bins with 32" sidewalls.

As a result of laboratory tests, SILOPRO stiffeners are in G-115 ( 350gr/m² ) standarts which are %25 stronger against colour casts and oxidation than G-90 standart stiffeners. Also %60 more protective than stiffeners produced under G-90 standarts.

SILOPRO stiffeners thickness from 4mm to 8mm are subjected to hot deep galvanising process. This allows 700-900 gr/m² amount of galvanize coating to the stiffeners.

SILOPRO stiffeners are designed according to standart of (American Iron and Steel Institute (AISI)) 'ASTM A653 Grade 50 Steel? have minimum 4.570kgf/cm² (65,000 PSI) tensile strength. This causes a serious superiority against other silo manufacturers in the market.

8,8 quality high strength decromat 500 a coated bolts are used in all sheet connection places in order to obtain highest degree of durability of all SILOPRO silos. Special caulking is used in all silo body sheets and upper cone connection points in order to obtain full air imperviousity and full waterproofness.

Bolts

8.8 quality high strength decromat 500 a coated bolts are used in all sheet connection places in order to obtain highest degree of durability of all SiloPro silos

Special caulking is used in all silo body sheets and upper cone connection points in order to obtain air and water tightness.

Splices

SILOPRO stiffeners feature strong splice joints with large cross sectional areas, both critical elements of vertical stiffeners. Splices thicknesses vary from 4mm to 8mm according to the design.

Ladder Systems

SILOPRO ladder and platforms are produced completely modular from galvanised sheets. The holes; drilled to the strip sheet metals by CNC Punching Machine gives easiness to bolt assemble.

Both external and internal ladders can be assembled to the existing holes by using connection fittings . The standart silo external ladder safety cage system enables people to reach the roof safely.

An eave platform can be installed below the manhole for your convenience when entering the bin or inspecting the roof.

Access to the roof and the rest platform to observe from manhole are SILOPRO's standart silo accesorries.

Rest Platforms

Silopro ladder and platforms are produced completely modular from galvanised steel sheets. The holes; drilled to the strip sheet metals by CNC Punching Machine, gives easiness to bolt assemble. Both external and internal ladders can be assembled to the existing holes by using connection fittings . The standart silo external ladder safety cage system enables humans to reach the roof in safe.

An eave platform can be installed below the manhole for your convenience, when entering the bin or inspecting the roof.

Both external and internal ladders can be assembled to the existing holes by using connection fittings . The standart silo external ladder safety cage system enables people to reach the roof safely.

An eave platform can be installed below the manhole for your convenience when entering the bin or inspecting the roof.

Access to the roof and the rest platform to observe from manhole are SILOPRO's standart silo accesorries.

Roof Systems

Our aim for designing the silo roof with 30° degree inclination is to easily flow out the moisture in the silo. During the ventilation, it also helps the air to flow out easily.

SILOPRO roofs are produced to be resistant upto a maximum peek load from 15.000lb. to 30.000lb. During designing, we consider values as a standart in snow load 40lb/ft and in wind load 90mph.

Silos between 3.65 mt-12.80 mt diameters have roof structure supported on a single stage. This type of roof structures are suitable to carry loads up to 907kg (2.000lb.) and have resistance against 78 kg/m² (16 psf) alive loads.

In 14.63 mt diameter and above silos,we use CNC bending twisted double stage beams. This type of roof structures are suitable to carry loads up to 4.536 kg (10.000lb.) and have resistances against 122 kg/m² (25 psf) alive loads.

SILOPRO roof panels are triangle in shape and both sides of the panels are roll formed as a 90 mm deep trapeze. There are inspection covers on each silo roof providing entrance in to the silo when the grain level is above the sidewall access door.

Wind Rings

SILOPRO wind rings mounted on the body of the silo, provide stable structure to the silo during filling and disharge. During the discharge process, silo opposes the pressure and stress of the side walls by the help of these rings. This allows you to use your silo with confidence for many years.

SILOPRO wind rings can also be used in the roof to strength the construction as used in the silo body sheets. SILOPRO wind rings are mounted on the silos according to the diameter of the silo, seismic zone and side discharge gates.

Fans

SILOPRO carefully prepared the ventilation products to meet your needs. These products and systems are fully galvanized, motor efficiency using the optimal relevance, special designed products.

The air flow of the stored grain can be possible with only proper ventilation equipments. SILOPRO aeration system equipments prolong the life of your grains with ventilation naturally and cooled.

SILOPRO ventilation systems are designed to decrease damage percentage of the grain, level of humidity and rate of insects in order to reduce risk of grain spoilling

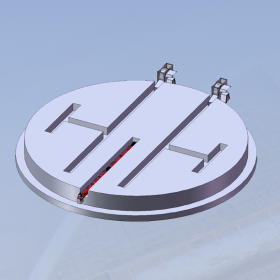

Floors

SILOPRO ventilation grids laids on the ventilation channels of the silo base.

-Through the grid structure and bottom supports, it has a design to carry thousands of grain.

-Through the perforated structure, it easily transmit the air flow inside the grain coming from the fans. Due to the special design, it prevents the fall of cereal grain in to the channells.

SILOPRO entirely produces ventilation grilles with galvanized products not to allow your grains to contact any coated surface.

Augers

SILOPRO also offers a full line of grain bin unloading equipment including unloads, power sweeps, roof augers, clean sweeps, power heads, and more. When it comes to getting the grain moving nobody gives you more options than SILOPRO.

Exhaust Fans

SILOPRO roof exhausters help your aeration fans effectively control grain spoilage in storage bins with flat or pitched roofs. These high volume fans produce the effective sweeping action needed to reduce condensation on the top of your grain.

For best operation, exhausters should run continuously while aeration fans are on, then long afterwards to assure removal of humid air from the overspace.

Vents

SILOPRO roof vents situated in silos are manufactured to be mounted on the roof. Vents that entirely produced with bolts are also assembled to the roof with bolts. Seal elements that are used during assemble of the roof vents, protect %100 of that region against rain water.

SILOPRO roof vents are designed to carry out the warm air from the silo and during this process to prevent any object to enter inside the silo.